This course is designed to provide a strong, functional understanding of Lean techniques; including how to effectively implement Kanban. It will teach techniques to plan and manage your workflow while reducing the impact of bottlenecks and other impediments.

During this comprehensive two day workshop, the participants will:

- Gain a comprehensive and clear understanding of Lean techniques, and how these can improve ongoing business processes.

- Learn how to optimise workflow, reduce ongoing costs, and improve staff satisfaction.

- Learn that Kanban means more than just putting cards on a wall.

- Participate in workshops to improve progress tracking and reporting.

- Discover how to engage the entire organisation in process improvement.

Who Should Attend?

This course is for managers, project managers, business analysts, engineers and developers who are interested in learning about Lean techniques and how they can help improve the quality and responsiveness of their work and workflow. The material covered in this course is applicable across industries, including software development, engineering, and manufacturing.

OUTLINE

- A Brief History of Lean

- The Relationship to Agile Techniques

- Deming’s 14 Points for Managers

- Toyota Production System (TPS)

- Understanding Waste

- Mura (Unevenness): Managing variation in workflow.

- Muri (Overburden): Managing unrealistic expectations and poor planning.

- Muda (Waste): Reducing wasteful processes.

- Value Stream Mapping: Analyse and plan the flow of materials and information that are required in the production process.

- Five S: Quality & continuous improvement processes (Sort, Set in Order, Shine, Standardize, Sustain)

- Managing Process Policies

- Kanban

- The Modern Kanban Method

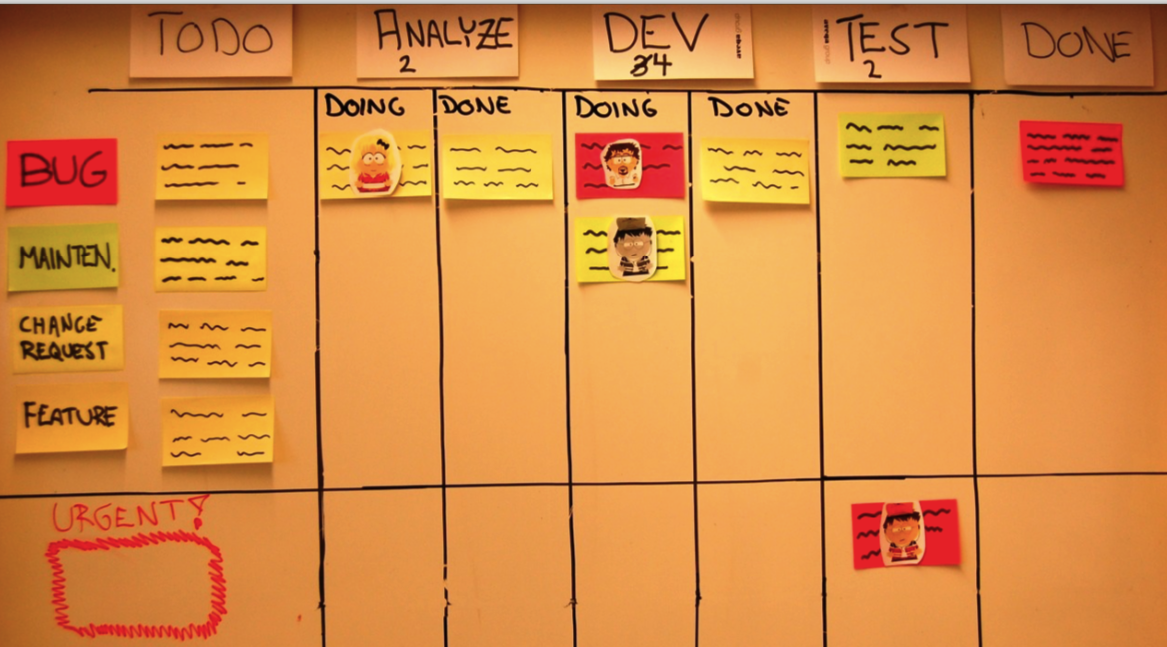

- Kanban Boards

- Workflow States

- Pull!!!

- WIP Limits

- Identifying and Managing Bottlenecks and Constraints

- Monitoring Flow and Metrics

- Cumulative Flow Diagrams

- Statistical Control Charts

- Fail-proofing: Prevent human errors before they occur.

- Levelling: Ensure that each step in the process delivers at a constant rate so that subsequent steps can also deliver at a constant rate.

- Lean Collaboration and Feedback Loops.

- Kaizen (Continuous Improvement): The ongoing, incremental and regular technique of improving all processes.

Lean is a streamlined development, manufacturing and production technique as well as a philosophy that aims to reduce costs by eliminating all ‘wasteful’ processes. Put another way, Lean focuses on ‘getting the right things to the right place at the right time in the right quantity to achieve perfect workflow.’

This two day workshop provides a practical grounding in Lean techniques and how these can be used within your organisation. This workshop aims to provide the tools for managers and teams to improve their workflow, reduce waste and regain control of their processes. The workshop uses fun and interactive scenarios which provide practical experience in using these techniques.